Exair Light Duty Line Vac

The exair line vac is a tried and true device for conveying parts materials and waste with no moving parts.

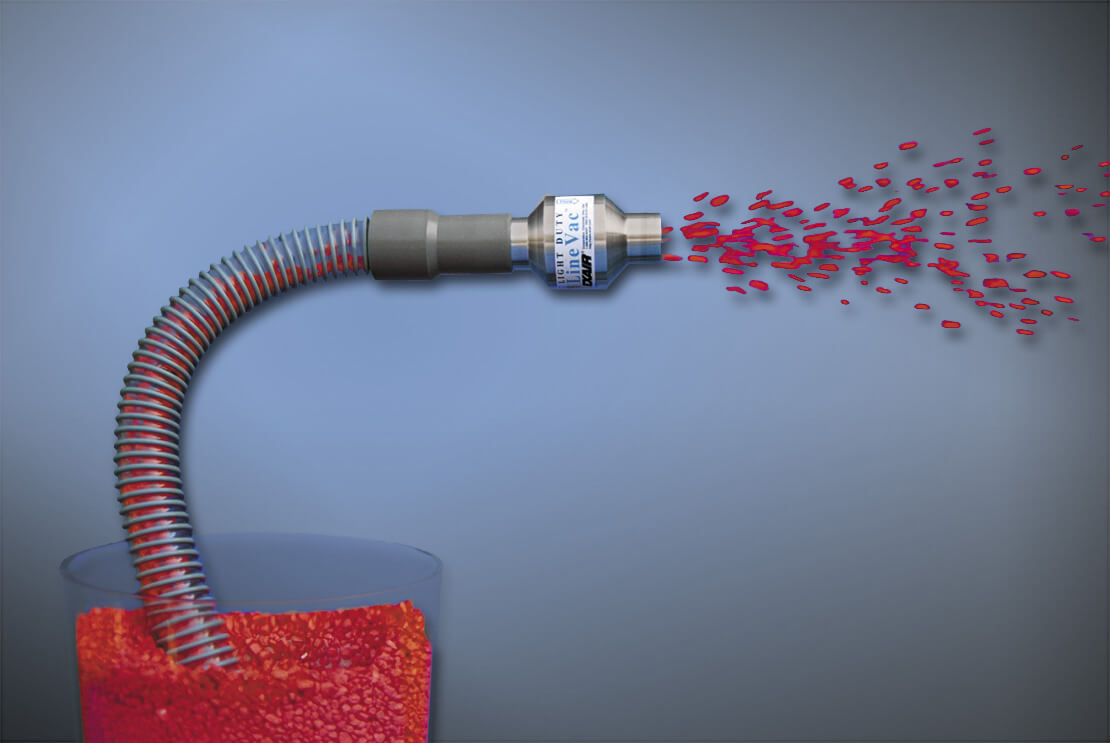

Exair light duty line vac. Cancer and reproductive harm www p65warnings ca gov product. Click here for promo. Line vac air operated conveyors are the low cost way to transport complex shapes bulk solids and waste with no moving parts or electricity. This was perfect for the company above.

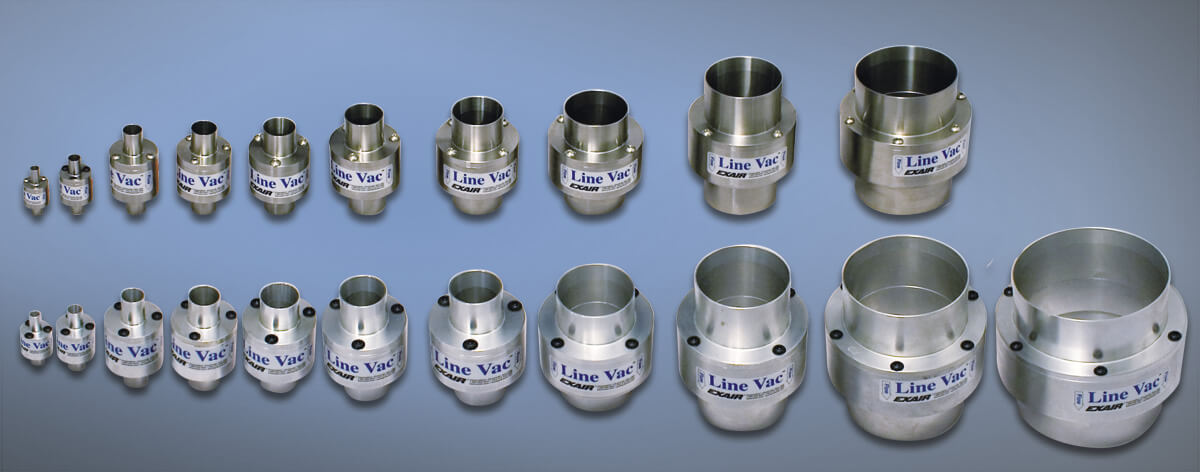

They are offered in 4 types of materials aluminum type 303 and type 316 stainless steel and a hardened alloy construction. Light duty line vacs. For short distance and light materials exair has the light duty line vac for conveying. Exair manufactures air operated conveyors to move product from one place to the another.

The exair family of line vacs. Exair s light duty line vac is the ideal way to convey small volumes of materials over short distances. Exair s compressed air operated line vac connects to standard hose or tube to create a powerful in line conveyor. Line vac conveyors are ideal for moving large volumes of material over long distances.

Exair manufactures 3 styles of line vac light duty standard and heavy duty with either smooth bore hose or npt threaded ends. The heavy duty line vac has been engineered to convey materials over longer vertical and horizontal distances. An important factor in material selection is the abrasiveness of the material to be conveyed. For short distance and light materials exair has the light duty line vac for conveying.

Light duty line vacs. Like the line vac the light duty line vac converts an ordinary hose or tube into a conveyor for scrap trim and bulk materials. Exair manufactures air operated conveyors to move product from one place to the another. The material flow rate is easily controlled.

The light duty line vac are made to use a range from 19mm to 6 152mm diameter hoses for conveying. The compact design features large throat diameters for maximum throughput capability. They are offered in 4 types of materials aluminum type 303 and type 316 stainless steel and a hardened alloy construction. They use less compressed air than the more powerful cousins like the.

This was perfect for the company above. The light duty line vac are made to use a range from 19mm to 6 152mm diameter hoses for conveying. The list of successfully conveyed materials in the application database is far reaching including plastic pellets scrap trim chips pills tablets shavings sawdust and granules. An important factor in material selection is the abrasiveness of the material to be conveyed.

The hardened alloy construction helps prevent premature wear that could occur with ordinary aluminum or stainless steel line vacs. The exair family of line vacs. The heavy duty line vac is exair s most powerful conveyor. The appearance is similar to the standard line vac but performance has been boosted dramatically.

A small amount of compressed air is injected through directed nozzles to produce a vacuum on one end and high output flows on the other with instantaneous response.